The new Gear V3 is here!

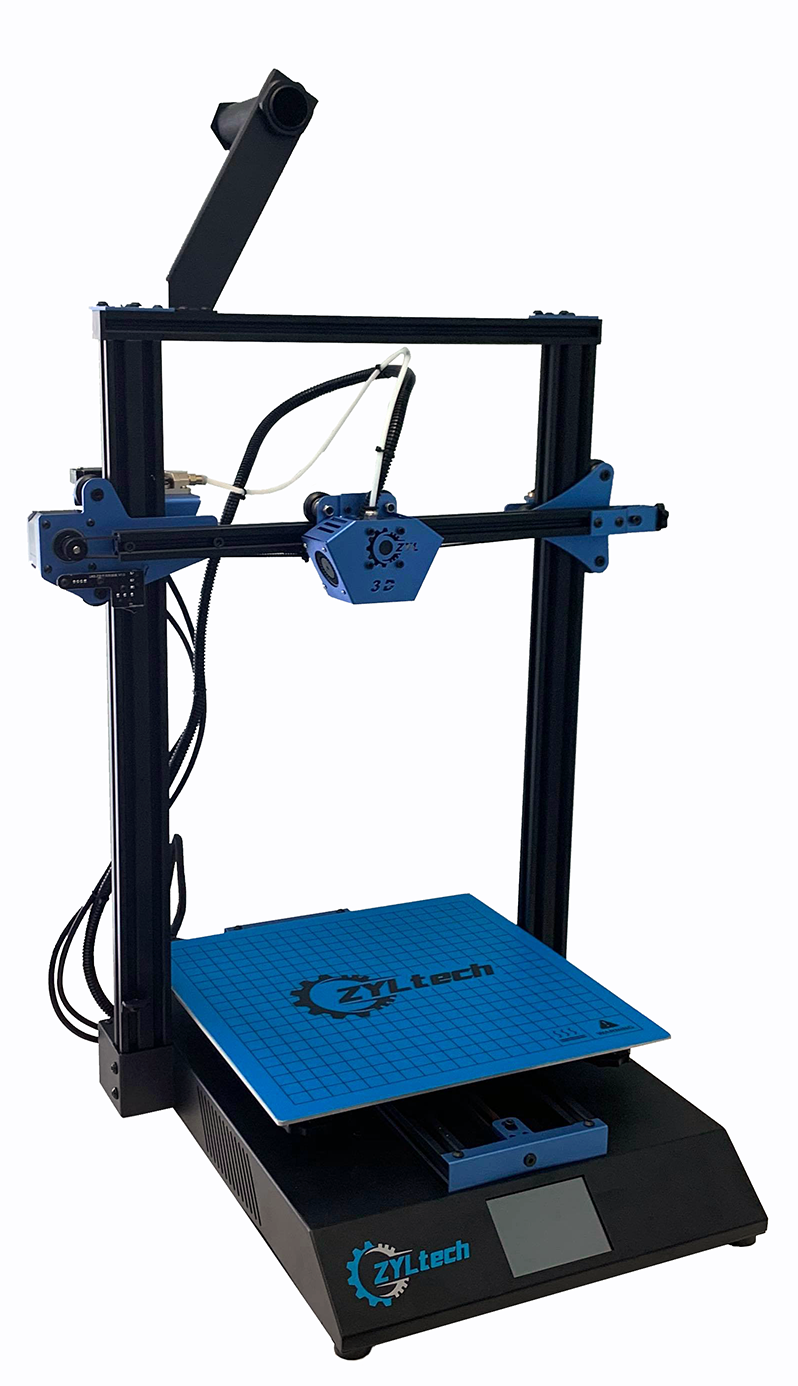

The new version has retained the great features of the V2 while making improvements that add quality to your prints.

New Improvements:

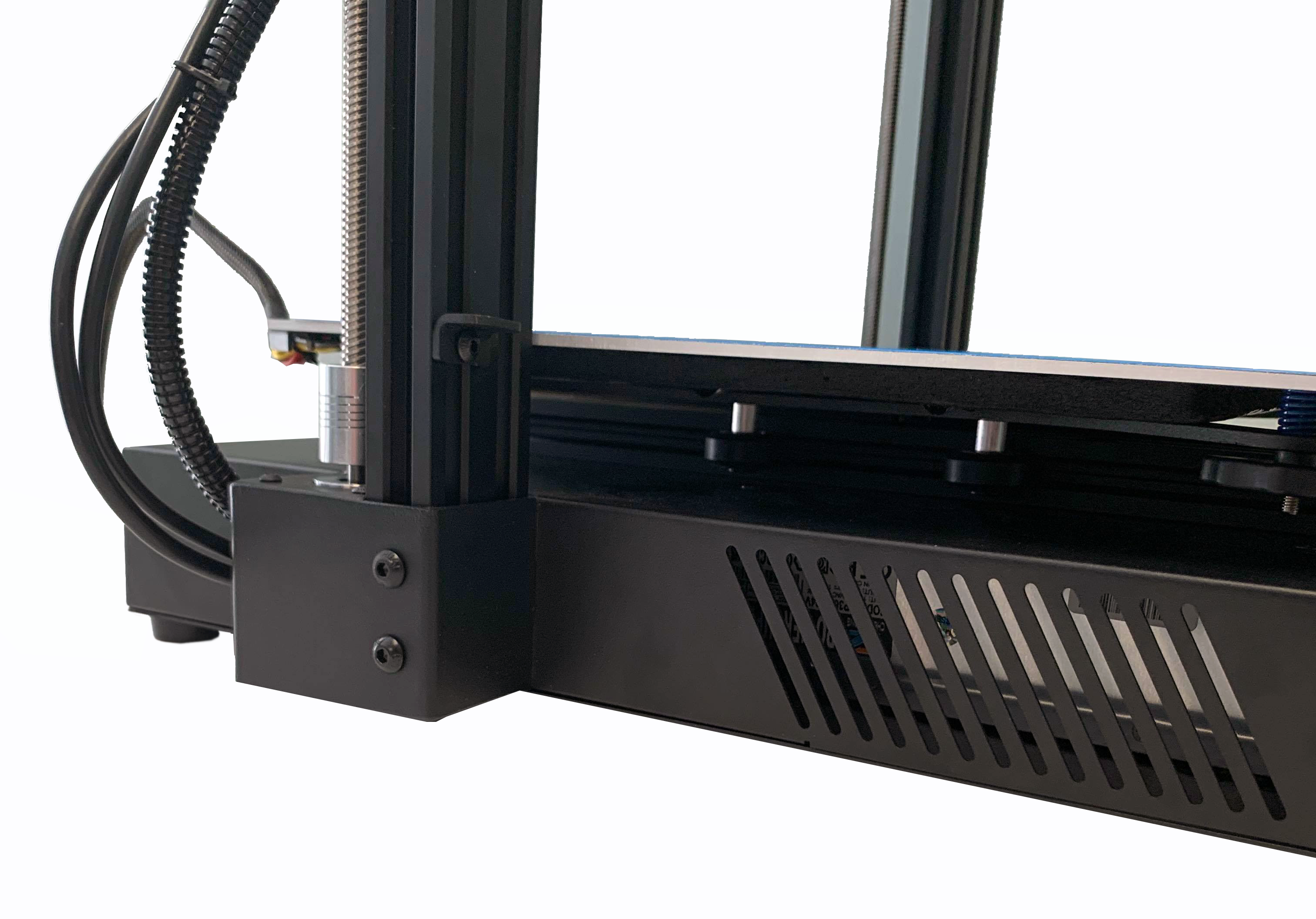

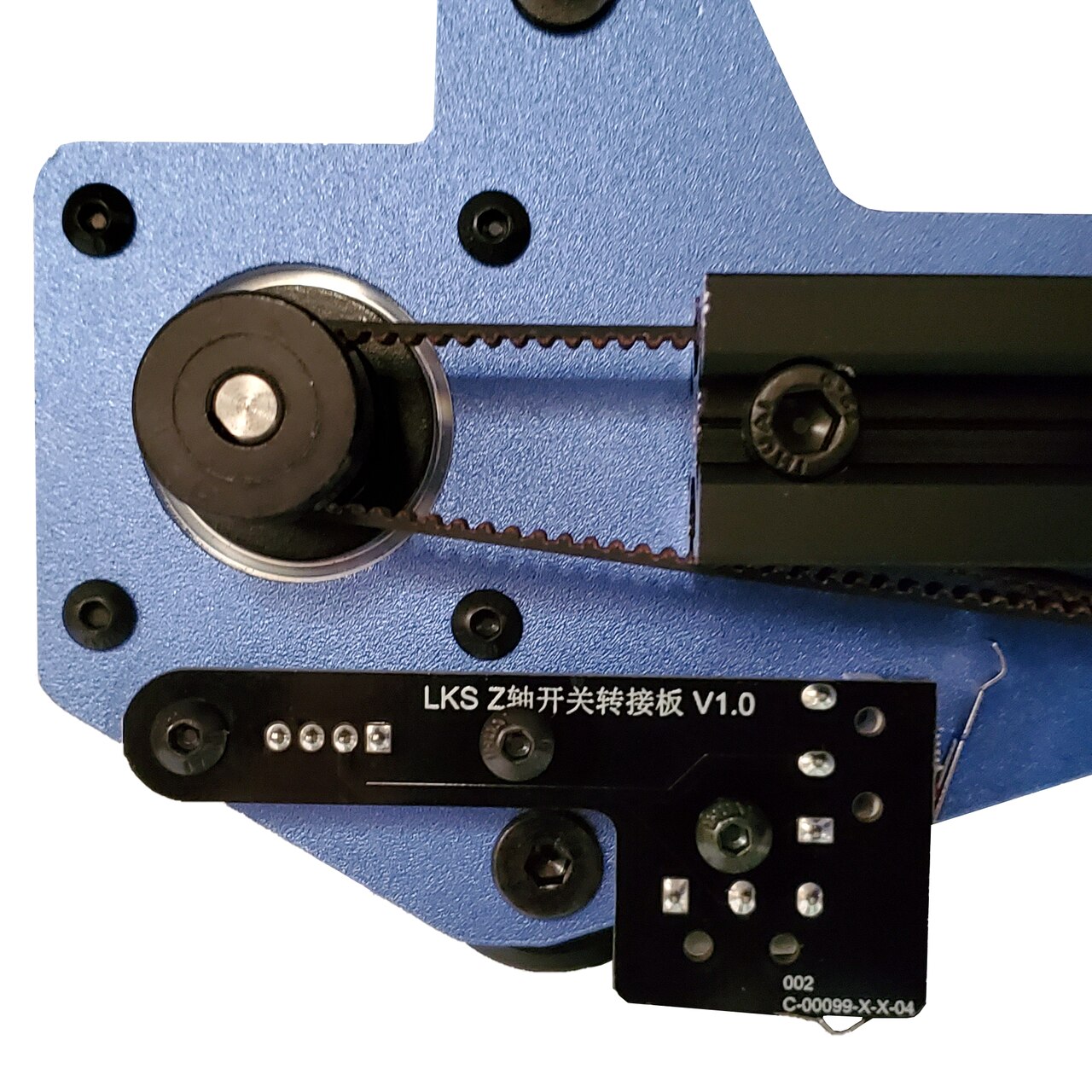

- New printer body now houses Z motors and adds structural rigidity and stability to the Z gantry

- Parts cooling fans now include fan ducts to direct air to where it is needed most

- Included silicone sock for the heat block for more stable temps

- Our heated bed is now insulated for more consistent temps

- Improved spool holder for smoother spool rotation

- Improved cable management internally and improved overall QC

Same Great Features:

- Same large 300x300x400 build volume

- Full metal construction with no printed parts

- Easy to install X and Z end stop assembly

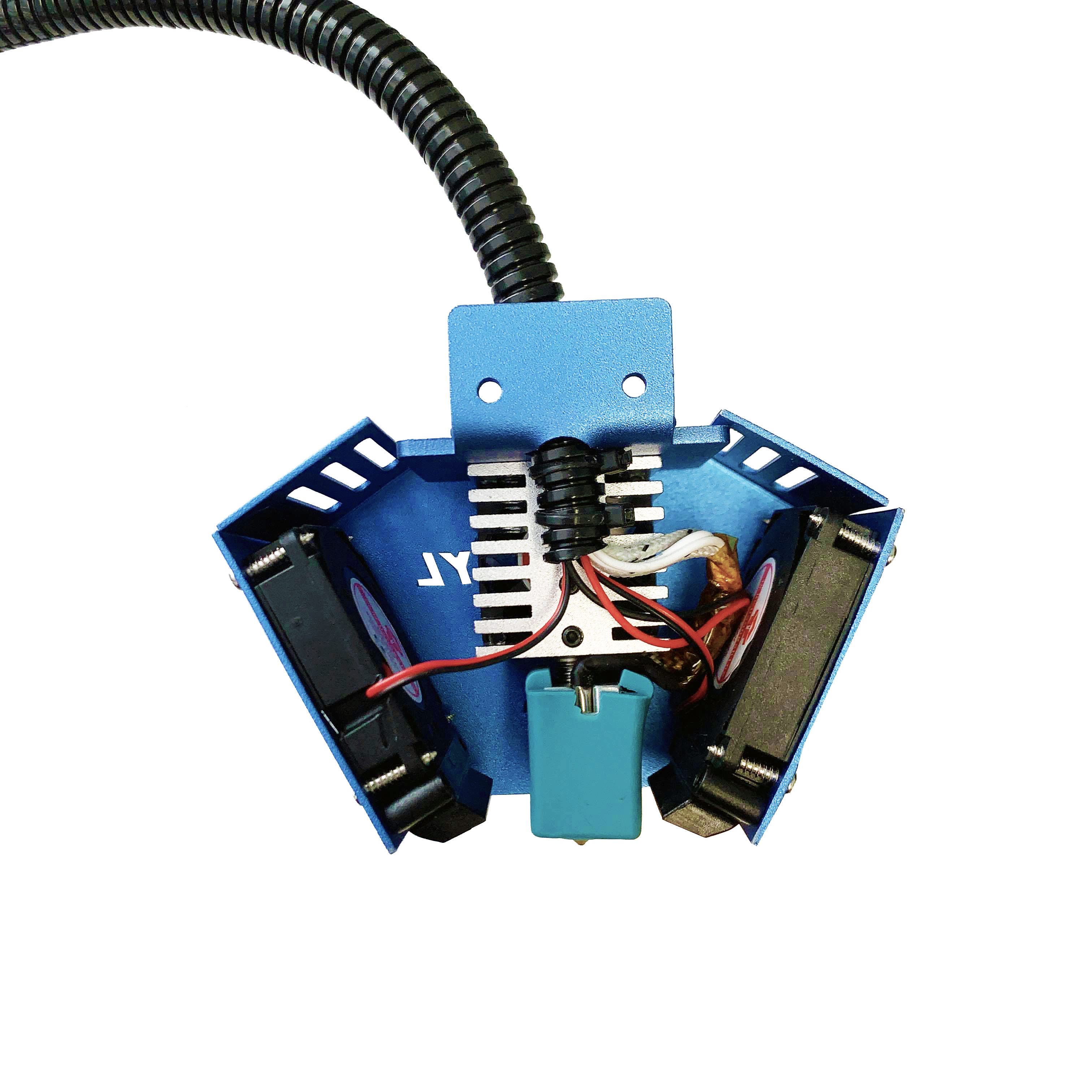

- Volcano style hotend with oversized heat sink and dual parts fans

- Same whisper quiet TMC2208 drivers on X and Y

- 32 bit controller with 3.5" color touch display Marlin 2.0 compatible

- Built in belt tension adjustment and dual Z motor synchronizing belt

- Smooth and precise .9 step angle stepper motors on X and Y

Resources:

Assembly Instructions

Firmware and firmware update instruction

Slicer factory file FFF (This format works with a variety of slicer programs)

FAQ:

Q. What are the carriages made of on the ZYLtech Gear V3?

A. The carriages are made of laser cut anodized aluminum plates, high strength/bolts and durable nylon wheels.

Q. What type of Control Board is included?

A. A MKS Robin Nano V1.2 with firmware installed. (Marlin 2.0 compatible)

Q. Can you print with a SD card?

A. Yes, a 4 GB Micro SD and USB adapter are included.

Q. Are the heated elements 12V or 24V?

A. Both the heated bed and hot end are 24V. All fans are 24V as well.

Q. What hot end does the ZYLtech Gear V3 use?

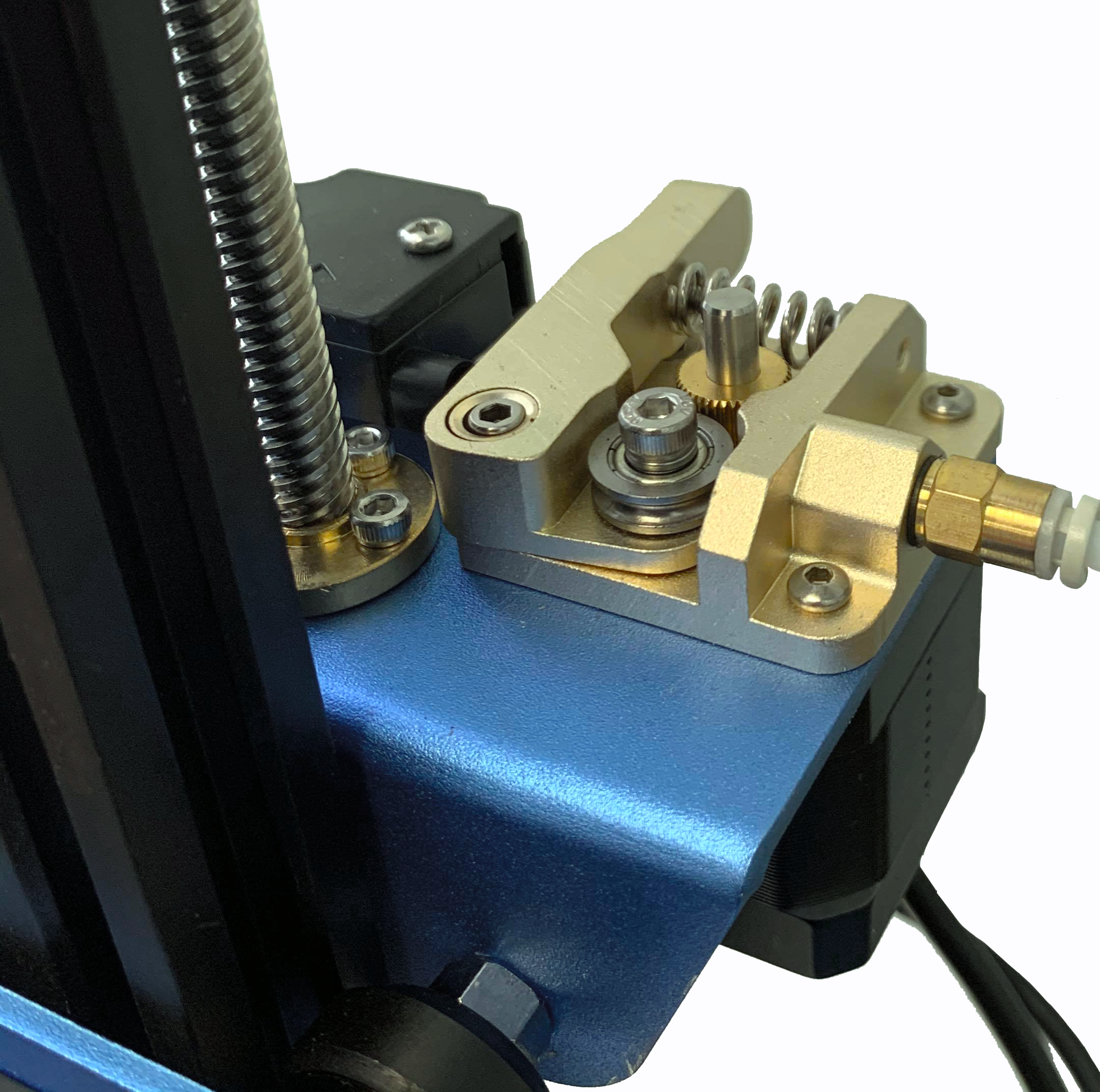

A. The ZYLtech Gear V3 uses a Bowden drive Extruder with a volcano style hotend. It is compatible with volcano style nozzles up to 1.2mm in diameter. The hotend has a 4mm bore allowing the PTFE to be fed directly to the brass nozzle. The high flow rate hotend is essential for large prints up to 300x300x400mm.

Q. What is the print bed made of?

A. The bed is made of 3mm aluminum with a plastic build surface similar to Buildtek. Glass bed upgrades are available. The maximum heating output is 240w. It only takes a few minutes to heat to 60C. We recommend printing at approximately 45C for PLA and 55C for PETG if using our blue PEI build surface.